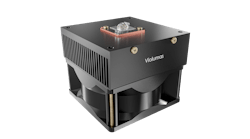

Global custom engineered thermoplastics compounder RTP Company has introduced a line of thermally conductive compounds for replacing metal heat sinks and housings in light -emitting diode (LED) luminaires. The new compounds have been specially formulated to increase the thermal management design options available for LED lighting as it expands into a broader range of enduse markets including automotive, industrial, retail, and consumer goods.

“The lighting market is undergoing a dramatic shift from incandescent to LED light sources,” said Neil Hardwick, Conductive Products Marketing Manager for RTP Company. “LEDs currently comprise less than 10% of the overall lighting market, but their share is predicted to rise to 80% over the next five years. To achieve that growth, new luminaire designs will be necessary and RTP Company’s thermally conductive compounds will make those designs possible.”

Reduced energy consumption and longer service life are some of the benefits of LEDs over incandescent and fluorescent lighting. “However, LED luminaires must include proper thermal management or the life of the LED is dramatically reduced,” said Hardwick. “RTP Company’s thermally conductive compounds will provide lighting designers with the creative flexibility to have thermal heat sinks and housings produced using injection molded plastics rather than from cast or machined aluminum.”

RTP Company’s thermally conductive compounds offer many benefits over aluminum in LED heat sink applications. The thermoplastic compounds reduce weight by up to 50%, injection molding processing simplifies and lowers manufacturing costs, inherent color eliminates the need for painting or secondary operations, and heat sink life is increased in wet environments due to plastics corrosion resistance.

As a custom compounder, RTP Company has the ability to modify these thermally conductive compounds to meet the performance requirements of specific LED lighting applications. A variety of additives achieve in-plane thermal conductivity up to 35 W/(m·K) and allow the compounds to be either electrically insulative or conductive. Additionally, UL94 flame retardance, white colors with reflectivity greater than 95% and UV resistance can be included to optimize each formulation.

Thermally conductive properties can be incorporated into a variety of thermoplastic resin systems including nylon 6 and 6/6, polyphenylene sulfide (PPS), and polycarbonate (PC) among others. All compounds are available globally from RTP Company’s network of full-service facilities that provide technical support from design through production.

In addition to thermally conductive compounds for LED luminaires, RTP Company also provides LED light-diffusion solutions for applications that incorporate LEDs. These materials eliminate visible hot spots from point light sources to provide a uniform appearance. Also, color correction can moderate color variations among LEDs.

For more information on RTP Company thermally conductive or custom engineered thermoplastic compounds, call (800) 433-4787 or (507) 454-6900, or visit their website at www.rtpcompany.com

“The lighting market is undergoing a dramatic shift from incandescent to LED light sources,” said Neil Hardwick, Conductive Products Marketing Manager for RTP Company. “LEDs currently comprise less than 10% of the overall lighting market, but their share is predicted to rise to 80% over the next five years. To achieve that growth, new luminaire designs will be necessary and RTP Company’s thermally conductive compounds will make those designs possible.”

Reduced energy consumption and longer service life are some of the benefits of LEDs over incandescent and fluorescent lighting. “However, LED luminaires must include proper thermal management or the life of the LED is dramatically reduced,” said Hardwick. “RTP Company’s thermally conductive compounds will provide lighting designers with the creative flexibility to have thermal heat sinks and housings produced using injection molded plastics rather than from cast or machined aluminum.”

RTP Company’s thermally conductive compounds offer many benefits over aluminum in LED heat sink applications. The thermoplastic compounds reduce weight by up to 50%, injection molding processing simplifies and lowers manufacturing costs, inherent color eliminates the need for painting or secondary operations, and heat sink life is increased in wet environments due to plastics corrosion resistance.

As a custom compounder, RTP Company has the ability to modify these thermally conductive compounds to meet the performance requirements of specific LED lighting applications. A variety of additives achieve in-plane thermal conductivity up to 35 W/(m·K) and allow the compounds to be either electrically insulative or conductive. Additionally, UL94 flame retardance, white colors with reflectivity greater than 95% and UV resistance can be included to optimize each formulation.

Thermally conductive properties can be incorporated into a variety of thermoplastic resin systems including nylon 6 and 6/6, polyphenylene sulfide (PPS), and polycarbonate (PC) among others. All compounds are available globally from RTP Company’s network of full-service facilities that provide technical support from design through production.

In addition to thermally conductive compounds for LED luminaires, RTP Company also provides LED light-diffusion solutions for applications that incorporate LEDs. These materials eliminate visible hot spots from point light sources to provide a uniform appearance. Also, color correction can moderate color variations among LEDs.

For more information on RTP Company thermally conductive or custom engineered thermoplastic compounds, call (800) 433-4787 or (507) 454-6900, or visit their website at www.rtpcompany.com

Contact:

RTP Company+1-800-433-4787

+1-507-454-6900

E-mail:

[email protected]Submit new products, case studies/projects, and other press releases at http://www.ledsmagazine.com/content/leds/en/addcontent.html and http://www.ledsmagazine.com/content/leds/en/iif/add.html.