This article was published in the June 2012 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete June 2012 issue, or view the E-zine version in your browser.

+++++

Luminaire or light-engine designers have a broader portfolio of packaged LEDs to choose from than ever before. The mainstream single-emitter, high-power LEDs offer greater efficacy than even the most optimistic prognosticator would have predicted a few years ago. But LED makers are also slicing and dicing the finished wafers and combining multiple emitters in a package in a variety of ways to meet specific requirements such as a high-input voltage for a simpler driver. At the other end of the spectrum, manufacturers are leveraging the plastic packages developed for low-power LEDs for backlighting and combining lighting-class phosphor technology and testing to offer a new approach to some applications such as linear lighting.

Over the course of the last couple of years, however, the top manufactures have significantly expanded their portfolios. They have continued to push efficacy, but have also optimized packages, turned to arrays of emitters, and delivered many options in forward voltage.

The impetus for the change has come from an increasingly fragmented lighting market with numerous types of end products. Ray Chock, global segment marketing manager at Philips Lumileds, said, “We are providing application-specific LED solutions for the fragmented segments.” Still, high efficacy and low cost are the primary avenue to more SSL uptake and Chock said that the LEDs in the broader Lumileds portfolio were conceived “trying to optimize system efficiency and cost.”

Larger LED packages

Let’s jump right into a discussion of larger packages as an example of the diversity of LED offerings. Osram Opto Semiconductors recently introduced the Soleriq E series (Fig. 1) of LED arrays that come in 30×30-mm and 36×36-mm packages. The series includes products that range from 1500-4500 lm output in a single package, and efficacy hits 103 lm/W in a 4000K CCT model.

Brian Terao, director of SSL products at Osram, said that the large package with a single optic simplifies the coupling of the source to secondary optics and ultimately the luminaire design. Terao also said, “We were looking ahead to comply with a Zhaga standard.” While Zhaga doesn't specify LED type, Terao said the Soleriq form factor will simplify the design of some Zhaga-compliant modules.

The Soleriq series is based on multichip arrays with the emitters connected in parallel and series with a number of configuration options. You can choose models with forward voltage as high as 44V.

Other vendors offer components based on a chip-on-board (COB) package similar to Soleriq. Nichia, for instance, announced the NSBWl110 and NSBLL110 products last fall that measure 16×19 mm, and output 990 to 1230 lm. And Cree targets non-directional applications with the XLamp CXA2011 that measures 22×22 mm and outputs as much as 1040 lm.

Efficacy gains enable smaller die

But not all of the activity is at the large-end of the package spectrum. Indeed Cree kicked of the year announcing the 2.45×2.45-mm XLamp XB-D series (Fig.2). The series tops out at 136 lm/W in efficacy and at 139 lm in output. Increased efficacy, in part, enabled the announcement as Cree’s mainstream single-emitter product family measures 3.5×3.5 mm. Cree said at launch that the XB-D outperformed competitors' 3.5×3.5 mm products.

Subsequent to the XB-D launch, Cree announced the XT-E family that matches the 3.5×3.5-mm footprint of the mainstream XP-E family. The XT-E offers double the efficacy of the XP-E predecessor, hitting 148 lm/W in cool white. Cree said the new devices would be priced the same as the predecessors, although that’s a significant decrease in dollars per lm.

In addition to efficacy gains, there are other design elements in single-emitter LEDs that are application specific. For example, Lumileds announced the Luxeon A series last year. The product was one of the first in the company’s Freedom From Binning program that includes hot testing and binning within a 3-step MacAdam ellipse.

Lumileds’ Chock said “Luxeon A offers the best color over angle on the market.” The Luxeon A uses a phosphor plate on top of the die and phosphor coating on the sides of the die. Chock said the product is widely used in professional-lighting applications.

Multichip architectures

Still it's in multichip packages that the manufacturers are offering the greatest diversity and application-specific features. Chock said "The flux density goes up with multichip packages." In actuality, multichip packages can provide several advantages and in some cases the packages are small and the flux output is low.

For example, Cree announced a series of what it calls high-voltage LEDs last year (www.ledsmagazine.com/news/8/10/34) and followed up recently with new products in the XT-E and XM-L families (www.ledsmagazine.com/news/9/4/4). The smaller of the products measure 3.5×3.5 mm and all of the products target small retrofit lamp applications.

The reason for the multichip approach is purely related to driver electronics. There is no optical benefit to the design, but by using multiple tiny emitters connected in series, Cree is able to offer an LED with a 48V forward voltage. For AC-line-powered applications, that higher input voltage translates to a simpler driver because the input voltage does not have to be dropped all of the way to the 3-4V level of a single emitter. Cree targets the products at small retrofit lamps such as candelabras.

Color matching

Moving up in package size, Cree also uses a multichip architecture in its EasyWhite LEDs to achieve color consistency. By combining a number of chips in a single package, Cree can produce components that, when the light is mixed, conform to a 2- or 4-step MacAdam ellipse. The newest products are the MT-G2 LEDs that measure 8.9×8.9 mm and can deliver 2100 lm at a 3000K CCT. Cree considers the products a good match for high-output, directional applications such as retrofits for halogen lamps. Cree will offer the MT-G2 products in a variety of configurations with input-voltage options of 6V, 9V, 36V, and 225V.

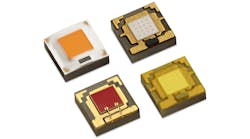

Lumileds, meanwhile, recently announced the multichip Luxeon M family (Fig. 3) that is designed for maximum light output and flux density, and outdoor- or industrial-lighting applications. The design includes 4 chips in a 7×7-mm package, and can produce up to 1100 lm.

The downside of larger LEDs, however can come in beam control. In an article about beam patterns back in 2010, most of the LED makers contended that smaller point sources with individual total internal reflection (TIR) lenses were ideal for maximum beam control. Essentially that remains true. Osram’s Terao said, “If you need to do some collimating, a large light source is not good.” But the flux density advantage has LED makers and luminaire designers working together to deal with larger sources.

Still, the luminaire designer has a choice. Lumileds also recently announced the Luxeon R that is a single-chip device, and that also targets outdoor applications. The LEDs can deliver up to 200 lm and come in a 3×4.5-mm package.

Mid-power LEDs

Perhaps the biggest news in the LED component space is the emergence of a mid-power class of LEDs that come in plastic packages and that are derived from low-end LEDs developed for backlighting, but that are getting lighting-class treatment from the manufacturers. At the Strategies in Light conference back in February, Ella Shum, director of the LED practice at analyst firm Strategies Unlimited, characterized mid-power LEDs as operating in the range of 0.1-0.5W.

The vendors are spinning similar stories about mid-power LEDs. The products being sold into lighting use phosphor technology that is more expensive and higher quality than the phosphor used in backlighting LEDs. The lighting-class devices are tested to LM-80 and designed for long life without lumen depreciation or color shift. We will see about those claims in time.

A common application for the mid-power LEDs is linear lighting. Fig. 4 shows an example with the Osram Duris devices. About linear lighting, Terao said “People want to see a nice continuous look.” The point is that more mid-power LEDs spaced closely together create more-even light than fewer high-power LEDs spaced further apart.

The danger of the plastic-package trend of course is that some lamp or luminaire makers, especially outside of North America, may buy the cheapest LEDs possible and end users may not get a pleasing experience from products that actually use backlighting LEDs.

For the LED makers, the motivation to offer lighting-class LEDs in plastic packages is murky. Are customers asking for the products, or are the manufacturers looking to use fab capacity that has been idled by the slowdown in the backlight market? As more than one person has said, you have to run your fab at capacity to maintain cost.