This article was published in the March 2012 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete March 2012 issue, or view the E-zine version in your browser.

+++++

Utility company San Diego Gas & Electric (SDG&E) has partnered with Hodad’s restaurant in downtown San Diego, California, to install LED-based ambient lighting in a demonstration of energy efficiency and high-quality lighting. The solid-state lighting installation uses LED-based, T8-retrofit tubes in the kitchen, LED A-lamps in the dining area, and LED downlights in corridors. After the project, SDG&E concluded that LED lighting can deliver energy savings ranging from 31% to 91% in restaurant applications.

While the goal of the demonstration was energy efficiency, quality of lighting was also paramount in the restaurant application. “We take lighting for granted but it’s so important in my business,” said Hodad’s owner Mike Hardin. “I always tell my customers that 90 percent of their taste buds are in their eyeballs.” Specifically, the lighting needs to render the colors in the food well; Fig. 1 shows one of the restaurant’s signature hamburgers under an LED A-lamp mounted in a suspended fixture.

A remodel of the space that would become the new Hodad’s was already underway when SDG&E’s Emerging Technologies Program got involved in the project. The contractor had installed 4-lamp lensed fluorescent troffers in the kitchen area spaced at 4-ft intervals in each dimension, totaling 52 lamps. In corridors, the contractor had installed recessed lights and planned to use 13 compact fluorescent lamps (CFLs) in those cans. A total of 42 incandescent lamps were intended for the suspended fixtures in the dining area.

LED lighting selection

SDG&E worked with lighting consultant Daryl DeJean of Emerging Technologies Associates to plan a conversion to LED lighting. Ultimately the team chose a 9W LED A-lamp made by Duracell, whereas the prior plan was for 95W incandescent lamps. Duracell is better known for batteries but has launched a line of LED retrofit lamps (www.duracelllighting.com). DeJean says that the LED lamps deliver 25-30 fc (foot-candle) at table level.

In the corridors, the team used a generic LED retrofit kit purchased at Home Depot in place of the CFL lamps. The 11W LED kits replaced what would have been 23W CFLs.

Fig. 2 shows a troffer fixture in the kitchen with owner Hardin at the work surface. The only lights in the restaurant that aren’t LED based are the CFL lights that are visible on the upper left side of the photo over the cooking surfaces. The project team felt that LED-based lights would not be a good match for the heat rising from the cooking equipment, given the need for heat dissipation in LED lighting.

The troffers that were installed were not of the so-called Super T8 variety that use both more-efficient lamps and ballasts to reduce energy. The fluorescent lamps would have dissipated 32W, but were replaced with 22W Duracell tubes.

Payback analysis

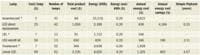

Table 1 summarizes the simple payback analysis of the project and is based on the following assumptions. The lights are on 5792 hours annually based on 16-hour days and the 362 days/year that the restaurant is open. The table presents a retrofit case meaning that payback factors-in the total cost of the LED lamps and fixtures used to replace the incumbent sources. In a new construction scenario where only the incremental cost of the LED lighting is considered, the payback drops considerably for both the downlights and T8 tubes to 1.44 and 3.88 years respectively.

Indeed, after the LED lighting had been installed for several weeks, Hodad’s workers reported that the lights in the kitchen were essentially too bright. SDG&E and DeJean experimented and ultimately removed two of the LED T8s from each troffer.

According to DeJean, the fixtures with four fluorescent tubes installed generated 40-50 fc at the task plane. With four LED tubes installed, the fixtures delivered 60 fc. With two LED tubes in each fixture the lighting at task level is in the 25-30-fc range and that’s appropriate for the application, said DeJean.

DeJean said that two florescent lamps would not have provided sufficient light levels, although three lamps per fixture probably would have been sufficient. But he attributed the superior performance of the LED tubes in the restaurant to directionality. While the DOE’s testing is without question accurate, it’s also clear that LED T8s are improving. For example, we also recently reported on a successful LED T8 case study in an Air New Zealand facility ().

Delamping improves payback

In the case of Hodad’s, the use of only two lamps has changed the payback analysis originally created by SDG&E. Compared to a 4-lamp fluorescent case, the LED tubes would achieve payback in a single year in the retrofit case and a bit sooner in new construction.

The project was a big win for Hodad’s. SDG&E’s Emerging Technologies Program covered the portion of the cost of the LED lighting that exceeded the cost of legacy lighting that met California Title 24 energy-efficiency standards. And Hodad’s owner Hardin said, “The new LED lighting makes my food look so good!”