ROLAND LEDYARD explains how 0-10V and digitally-connected LED drivers differ in functionality, and how those differences are manifested in commercial solid-state lighting installations.

One of the most persuasive words in marketing has got to be "free," despite the fact that we generally know that nothing in life is truly free, especially when it comes to LED drivers. Dimming functionality in drivers, implemented based on 0-10V controls, is sometimes touted as free, but in reality nearly every technology decision has a cost associated with it. Read along to learn about the issues with 0-10V LED drivers that can lead you to optimal selection and understand how more-robust digitally-addressable drivers may ultimately prove more economical in an actual solid-state lighting (SSL) project.

The adage that nothing truly comes for free is certainly true for 0-10V LED drivers. Many 0-10V LED fixture manufacturers offer dimming drivers as a no-cost upgrade versus what we will call switching drivers, or drivers that can simply be turned on or off via a relay or other control. The free 0-10V upgrade is intended to help manufacturers sell their fixtures to building owners, contractors, and specifiers.

Related article: FOCUS ON: Robust LED drivers are critical to enabling quality solid-state lighting

At first glance, when you are deciding between specifying an analog 0-10V dimming driver and a digitally-connected and -addressable dimming driver, it seems like an easy choice. With 0-10V drivers you get all of the benefits of LED dimming at no additional cost; however, it is not typically that simple. It is important to consider a variety of factors such as whether the dimming performance will meet your requirements, additional costs associated with meeting new codes and standards, and technologies that may not stand the test of time.

Overview of dimming LED drivers

Let's first step back and consider the dimming-driver technology options we are discussing here. A 0-10V control is an analog control type and the interface to the LED driver consists of two pairs of wires:

• A 120/240/277V line-voltage switch (Class 1 wiring)

• Low-voltage dimming control (Class 2 wiring)

Line voltage to the LED driver is switched in order to turn the driver on and off. A low-voltage control element such as a wall switch, meanwhile, delivers a control input to the driver by varying the voltage between 1 VDC (minimum light) and 10 VDC (maximum light). The driver associates this control input level to a particular dimmed level of the LED light engine. Since the control signal is a small analog voltage, long wire runs can produce a drop in the signal level, which results in varying light levels from different drivers managed by the same control device.

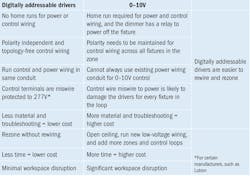

Digitally-addressable drivers are connected to controls via a digital interconnect such as DALI (digital addressable lighting interface). Lutron, for example, offers EcoSystem controls and drivers that are based on DALI (Fig. 1). Such a digital system addresses individual fixtures and provides status feedback from the loads, making it easy to digitally assign controls to one or many fixtures without complicated wiring. This opens up an entire suite of energy- saving and system-monitoring control schemes where the design and setup is all done within software, making the electrical and control design and installation simple. Power is circuited separately from control wires, so the 120V or 277V circuit can be fully loaded, making electrical design and installation easier. The table summarizes the differences in dimming driver types.

For an industry used to the significant increase in cost to go from switching fluorescent lights to dimmable fluorescent lighting, the cost to move from a switching LED driver to a 0-10V dimming driver is negligible. As a result, many fixture OEMs decided to offer dimming as a no-cost add-on to help sell their products. Customers often believe that the 0-10V LED driver will enable all of the same performance features as a digitally-addressable dimming driver and are surprised when they run into costly and time-consuming hurdles during installation.

Related article: Simplifying the sophisticated: LED driver selection made easy

There are certainly applications where 0-10V LED dimming drivers and controls are a good choice - for instance, in spaces where a consistent quality of light is not as important such as outdoor lighting, parking garages, and stairwells. We will help guide you through the specification process for such applications. In other spaces, the analog choice can result in issues that range from NEMA (National Electrical Manufacturers Association) 410 and inrush current compliance problems, to power-line noise interference, significant performance gaps, and the significant cost implications of having to rewire to accommodate changes in zoning or control when a space is repurposed or reorganized.

Digitally-addressable LED drivers can be reassigned and reprogrammed with no additional wiring or installation charges. Compatibility between LED lamps, drivers, and controls can be very confusing. It is important for specifiers to take the time to understand what they are really selecting so they don't pay a higher price down the road.

Nine questions to ask when specifying an LED dimming driver

Question #9 - Sink or source? In the case of analog controls, you need to know if your driver is sinking or sourcing current over the control interface. When you are using 0-10V LED drivers, in order to make sure your lights perform the way you expect them to, you will need to match the control type to the driver type, and these requirements vary depending on which standard your lighting is based on - IEC 60929 or ESTA (Entertainment Services & Technology Association) E1.3. In IEC standard 60929, the driver sources the current, and the control sinks the current. At 10V, lights will be on at full, and at 1V or below, lights go to a minimum level, not necessarily off. Using the ESTA E1.3 standard, the control sources the current, and the driver sinks the current. At 10V, lights will be on at full, and at 0V or below, lights go to off.

In a typical commercial setting, you can run into many different fixtures that use different methods of control. If you are using 0-10V drivers, it's critical to know whether the driver is sinking or sourcing current. This needs to be coordinated in advance, which can take additional time; moreover, a mistake can result in an expensive callback.

Digitally-addressable LED dimming drivers use different technology that is not affected by the control type or the lighting standard, although the control and driver must be based on the same interconnect technology such as DALI. Such a standard guarantees compatibility between drivers and controls, minimizing upfront time and effort, and making specifications easier.

Question #8 - Do the drivers comply with NEMA 410? NEMA 410 is a standard for testing of lighting controls used with electronic drivers, ballasts, and lamps. It defines the worst-case inrush current expected in installations and establishes test criteria for compatibility. In layman's terms, it works to avoid issues that result from the large buildup of current that can occur when you first turn on an LED driver. It's important that the controls and drivers are designed to handle the inrush current and don't exceed NEMA 410 standards when the lights are first turned on, potentially fatally damaging the dimmer and the relay.

Some 0-10V LED driver manufacturers provide inrush current specs, but they don't usually meet NEMA 410 requirements. In the typical case where there are several fixtures connected to one power and control circuit, the combined inrush in multiple drivers can cause currents to rise very high, which could result in a situation where users are unable to turn the lights on or off due to a failed switch, dimmer or relay contacts, or a tripped breaker. When this requires a call to maintenance, the costs may also include a new dimmer, driver, or fixture. Choose drivers and controls that meet NEMA 410 requirements, and ideally that have an electronic off that causes no inrush current.

Question #7 - Is it cost effective to run an extra wire in order to allow for battery-backup in emergency fixtures? In an emergency power situation, many emergency lighting systems rely on a battery backup inside the fixture in order to work. In 0-10V LED fixtures, this will require the contractor to run an extra hot wire for battery charging, and adds to the list of items specifiers need to coordinate when designing the lighting for a room. Digitally-addressable LED dimming drivers do not require a dedicated hot wire to charge the battery backup, making them easier and less costly to install in lighting with emergency capabilities.

Question #6 - What happens if the control wires are too close to the power wires? Standards do not specify whether 0-10V control wires should be run as UL Class 1 (line voltage) or Class 2. The decision is up to the driver manufacturer. Long wire runs typically used with 0-10V drivers can create noise and affect dimming range and accuracy. The same interference issues can occur if the wires are in the same conduit as power wiring. In order to guarantee performance, specifiers will have to do a good bit of homework to make sure the wires are run appropriately.

Characteristics of digital and analog dimming driver installations.Digital LED dimming drivers use digital communication that is immune to the noise, and they are designed to deliver the same performance regardless of how the project is wired. The dimming performance will not be adversely affected by either noise or long wire runs.

Question #5 - Are the drivers protected from miswires? With a 0-10V driver the wiring must maintain polarity and follow the line voltage zoning. Basically, if you accidentally miswire the unit, you can destroy all of the LED drivers in the system. While no one intends to miswire a driver, it happens - and with a 0-10V LED driver it can be an expensive mistake.

With digitally-addressable LED drivers, a miswire is very unlikely since the polarity of the wires does not matter. You can swap polarity without an issue, run the wires in any configuration (star, T-tap, daisy chain, etc.), and realize cost savings by not having to purchase additional conduit to separate the wires.

Question #4 - If a driver fails, the fixture UL Listing may be voided. How can you ensure UL compliance? One reason that specifiers select 0-10V LED drivers is because they ostensibly use an open technology and therefore the driver will be less expensive to replace if it fails. In order to maintain UL Listing and stay in compliance, however, UL requires that the entire fixture be replaced if the driver fails. Since an LED fixture is UL Listed with a specific LED driver, you also have the option to replace the failed driver with the exact same brand and model in order to maintain the UL listing, but you will still need a UL field inspection.

Indeed, 0-10V is an open protocol, but UL compliance requires the aforementioned driver selection and field inspection. In some cases, digitally-addressable LED dimming drivers are UL 1598C recognized, which means they can be part of UL Listed LED field retrofit kits and can be replaced, in the event of failure, without an additional inspection.

Question #3 - Do all of your 0-10V fixtures have consistent light level per control output? The Sacramento Municipal Utility District in Sacramento, CA commissioned a study on different 0-10V fixtures from various brands and found that no two different fixtures perform exactly alike. This is because 0-10V standards do not specify performance, so each manufacturer has its own interpretation of things like input, output, and turn-on time. If two 0-10V fixtures from different manufacturers are side by side in a room, there is a good chance that the light output will look different. One could be twice as bright and turn on more than two seconds after the other.

Generally, lighting is specifically designed to deliver a consistent, comfortable light quality. To ensure this quality with varying 0-10V LED fixtures, you need to evaluate the dimming curves for all of the LED drivers used together on a control circuit and make sure they track together.

Digitally-addressable LED drivers will turn on and track together to provide predictable, reliable results. When you want the lights to deliver 75% illumination, all the drivers will deliver the same light level at the same time, across different fixture types and driver models.

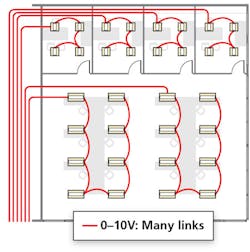

Question #2 - If you need to change zones, are you prepared to rewire? Let's face it, office layouts change, employees move around, and even the building lessee may change. Each of these changes will typically require you to change the lighting to reflect the new needs of the space or the employee. With 0-10V LED drivers, making changes to fixture zones or controls requires a complete rewire, both in design and in the field (Fig. 2). Even if you are still in the design phases, a zone change with 0-10V LED drivers will require your engineer to redraw how the fixtures are connected. Changes in design and in the field will also add cost when using 0-10V LED drivers, which - of course - will also contribute to higher project lifecycle costs.

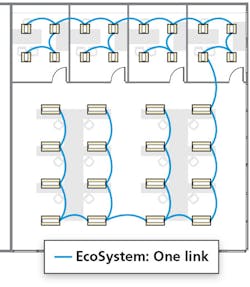

With digitally-addressable LED dimming drivers, you can defer zoning decisions until later and wiring is independent of such zoning (Fig. 3). Everything is done through the software so there is no need for rewiring or redrawing. Zoning decision and control assignment is software driven, and can be achieved at any time through the use of a smartphone, tablet, or computer. Lutron's EcoSystem, for example, makes it easy to digitally assign occupancy sensors, daylight sensors, time clocks, manual controls, and other controls to one or many fixtures without complicated wiring. This opens up an entire suite of energy-saving, system-monitoring, and system-control schemes where the design, setup, and rezoning are all done within software, making the electrical and control design simple.

Question #1 - Will your 0-10V LED driver manufacturer be able to resolve field issues? In the end, it always comes down to commitment and support. If you are in a situation where you have an issue with your lighting, do you feel confident your driver manufacturer will stand behind you until it's resolved? There are many instances where 0-10V driver manufacturers can't be reached for a phone call - much less a site visit - to resolve an issue due to a lack of local technical support. Getting a response is extremely difficult, leaving you on your own to address it as best as you can.

Choose a manufacturer who will offer you 24/7 support, with a large and local service organization, as well as a toll-free phone number that is printed, and easy to locate on every driver. If there is ever an issue, available service professionals - whether they are accessed by phone, e-mail, or in person - can get to the root cause and fix it. In the long run, choosing a company that is as committed to service as they are to product excellence is a key differentiator in terms of return on investment.

Drivers and compatibility

In SSL systems, issues with compatibility are probably the greatest source of frustration and cost among product developers, specifiers, and end customers. To avoid any of the hassles detailed in this article, look for lighting control manufacturers who have already done the appropriate testing and research, and who are committed to providing resources that help clarify the selection process. One such resource is the online LED Control Center of Excellence offered by Lutron Electronics. By choosing the right manufacturer and considering key issues, you will save time and money and it will be easier than ever to provide customers with an LED lighting and control system that meets energy-saving, performance, and aesthetic expectations.

ROLAND LEDYARDis a design and development manager at Lutron Electronics (lutron.com).