This article was published in the February 2013 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete February 2013 issue, or view the E-zine version in your browser.

+++++

LED-based retrofit lamps remain the most popular topic in the solid-state lighting (SSL) industry, despite the fact that a form factor such as the A-lamp does little to support the inherent advantages of LED sources. Still, the huge number of retrofit-lamp sockets installed around the globe make the retrofit lamp important to both lamp manufacturers and users looking to proliferate SSL technology and save energy. And while the basic size and type of socket may be fixed, manufacturers are taking vastly different approaches to try and win in what could be a short-lived market.

Many of the lamp-design topics we will discuss here could be examined relative to many different types of retrofit lamps. The potential list includes LED-based tubes designed for linear fluorescent sockets and directional and reflector products such as PAR, MR, and BR lamps. In this article, however, we will focus on omnidirectional A-lamps that are the most prevalent lamp in use.

You need look no further than at a list of the most popular articles on the LEDs Magazine website for 2012 for proof of the appeal of the topic at hand. More than 25% of the top 20 list had a retrofit lamp focus.

But ironically, the opportunity for companies to sell retrofit lamps is inherently limited. Socket saturation will occur fairly quickly. As we’ve reported previously, outspoken Tempo Industries CEO Terry Walsh predicted saturation within five years at The LED Show last summer.

Saturation will happen for two reasons. First, demand will drop as long-lasting LED lamps become predominant and don’t need to be replaced often. Second, purpose-built SSL luminaires will make much better use of LED sources and will become increasingly popular even in residential applications. For all of those retrofit-lamp startups out there burning through venture money, the message had better be get to market quickly. And for companies such as Philips Lighting, that may have invested more than anyone in retrofit lamp development, good job but get your money back in a hurry.

In actuality, there is still a huge opportunity. In a report issued in April 2012, Strategies Unlimited reported that there were $2.2 billion in LED-based retrofit lamps sold in 2011. The report projects 30% annual growth through 2016. But saturation could happen shortly after the 2016 timeframe.

Lamp design

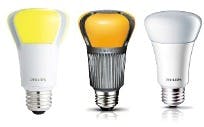

Having covered the market a bit, let’s transition to a discussion of the products and design approaches. We will start with Philips because of the noted success the company has had including with the US Department of Energy (DOE) L Prize winning lamp and the latest change to their design approach.

Philips has built retrofit lamps using a number of approaches, but is probably best known for the remote-phosphor-based designs that have a yellow or orange tint when powered off. As we covered in a recent contributed article, remote-phosphor designs that combine very efficient blue LEDs with phosphor on a secondary optic, provide an efficacy advantage over designs that use phosphor-converted white LEDs. Moreover, remote phosphor can provide more consistent color maintenance because the phosphor is not subject to the heat generated by the LED, and therefore doesn’t shift in color over time.

The Philips remote-phosphor design was first revealed several years back when the company announced their entry into the L Prize competition for a 60W-equivalent retrofit lamp. The company first commercialized the technology in the lamps sold under the EnduraLED and Ambient LED brands in different parts of the globe. Later, the company commercialized the L Prize winner that had to meet higher standards than the Energy Star-compliant EnduraLED products.

Fig. 1 shows the L Prize lamp on the left and the EnduraLED lamp in the center. The products share the same shape and both are based on three illumination chambers with air-flow channels between the segments for cooling. The LEDs are mounted near the center axis of the lamp in each segment on a vertical circuit board that’s approximately perpendicular to the center axis. The LEDs are directed outward and slightly upwards and downwards to deliver an omnidirectional beam.

Energy Saving LED A19 lamp

Philips new architecture

Interestingly, Philips just announced a new 60W-equivalent lamp family at the end of 2012 that maintains the general shape of the prior lamps, but that is white in the off state. The new design also eliminates the segmented approach (Fig. 1 on right).

Competitors had certainly questioned the look of the remote-phosphor lamps. And some specifiers would be unlikely to use the lamps in fixtures where the lamps are exposed. The Home Depot retailer even installed signs near EnduraLED lamps explaining to customers that the yellow or orange lamps emitted white light when powered on. Philips insisted all along that performance was more important than the off-state appearance of the remote-phosphor lamps. But the new design could mean that the company felt pressure to offer lamps with more of a legacy look.

Todd Manegold, director of LED lamps marketing at Philips Lighting, said, “We have been focused on replicating traditional sources.” He said the company first attacked the problem of delivering equivalent performance and the warm CCT of incandescent lamps, and now is addressing aesthetics.

Despite the similar shape of the lamps, which Manegold referred to as iconic and easily recognized as a Philips LED lamp, the new Philips Energy Saving LED A19 lamps are much different internally. The LEDs are mounted on a plane perpendicular to the center axis of the lamp, projecting light upwards into the light chamber. The optic itself must ensure that the lamps still deliver an omnidirectional distribution. And clearly the design works, because the 2700K version that Philips calls Soft White has already gained Energy Star status and Energy Star requires an omnidirectional beam distribution.

Philips is still using remote phosphor on the 2700K lamp, but the phosphor is applied on an inner dome that isn’t readily visible. The 5000K Daylight version of the lamp simply uses phosphor-converted LEDs. Manegold said that the company would be updating its 75W- and 100W-equivalent lamps to use the new design down the road, although the company just began shipping the 100W-equivalent EnduraLED product in December as we will discuss a bit later.

Best Buy Insignia lamp

While Philips moved to a planar mounting scheme for its LEDs, another new lamp on the market, the Insignia lamp from retailer Best Buy, took yet another approach to vertically mounting LEDs for good light distribution. Insignia is retailer Best Buy’s house brand for many types of consumer electronics including TVs. In November the company announced the SSL lamp along with Cree who is supplying the LEDs for the lamp.

The design looks white and somewhat like a traditional lamp, although you can clearly see the lamp is broken into three globe segments separated by what are apparently cooling surfaces (Fig. 2). What isn’t apparent is that the LEDs are mounted on the inside of those surfaces shining at the globe segment on the opposite side of the lamp. There is nothing in the center of the globe. The result is a well performing 13W lamp with a good omnidirectional beam and a price of $16.99 for a 800-lm 60W equivalent. Best Buy also offers a 9W, 450-lm 40W-equivalent lamp.

Rambus MicroLens

Another new approach to retrofit lamps comes courtesy of Rambus. The company is an intellectual property (IP) specialist that doesn’t manufacture products but rather licenses technology to other manufacturers. Its play in the lighting segment is a light guide technology called MicroLens that carries rays from the LED sources and includes small optical elements embedded within the layers of the guide to deflect some rays and provide a naturally diffuse light.

MicroLens has primarily been used thus far to develop flat planar lighting. GE Lighting is one licensee and recently announced a pendant luminaire based on the technology. Cooper Lighting and Fern-Howard have also licensed the technology.

In the case of the A-lamp that Rambus introduced at the Consumer Electronics Show in Las Vegas, Rambus has manufactured a pilot run of an end product but will still look to partners to ultimately bring the product to market. Elite Group will be the initial source for a 60W-equivalent A19 lamp due in the second quarter.

The retrofit lamp uses three cylindrically shaped MicroLens segments that essentially form a cylindrical lamp (Fig. 3). The LEDs are mounted in a circular fashion around the base of the lamp shining upwards into the light guide.

That claim of course depends on the cost of making the light guide. Moreover, it’s not clear that the design could meet Energy Star requirements that require uniform luminous intensity over a range of 0° to 135° with 0° being the top of the lamp. The lamp should deliver an even beam around the circumference of the cylinder. But it’s not clear that it could generate uniform light upwards and downwards.

3M LED Advanced Light

The Rambus lamp is the second product announced in the second half of 2012 to use light guide technology – the first being from another surprise market entrant 3M. The giant company is a materials specialist, and evidently saw a good chance to use a number of its materials technologies in a fast-growing market segment despite the fact that it hasn’t previously sold lighting products.

The approach depicted in Fig. 4 greatly simplifies the driver design, as the driver is located in the relatively spacious globe. Most other SSL retrofit lamps cram the driver into the base and/or neck of the lamp. The 3M design allows air to flow into the lamp just above the base and exit through slots in the upper half of the globe – cooling both the LEDs and the driver.

The result is an 800-lm lamp that is being sold at many Walmart stores for $25. 3M is offering both 3000K and 5000K versions. The warm-white version requires ten LEDs to deliver the specified flux, while the cool-white version uses nine LEDs.

100W-equivalent race

Perhaps the most exciting news over the course of 2012 in the retrofit lamp area was the race to offer the LED equivalent of a 100W lamp. Government regulatory guidelines around the globe are forcing 100W incandescent lamps from the market. Ironically, such regulatory agencies targeted 100W lamps first because they use more energy than lower-wattage lamps. But those higher-output lamps are also harder to design with LEDs because of the requirement of delivering on the order of 1600 lm and handling the associated thermal issues – drawing heat away from the LEDs to ensure reliable operation. The industry has eagerly sought an LED-based alternative.

Back at Lightfair International last May, we witnessed dueling 100W-equivalent news releases from the likes of GE Lighting, Switch Lighting, Philips Lighting, Lighting Science Group and Osram Sylvania). Most pledged to be first to market, but commercial delivery was far from certain in 2012.

It turns out thatOsram Sylvania won the race by a nose over Philips Lighting. In mid November some Lowes retail stores had the Sylvania Ultra LED 20W A21 lamps on shelves. Philips EnduraLED lamps shipped to Home Depot starting December 1. The other contenders have yet to ship products.

Sylvania Ultra LED

The Sylvania product (Fig. 5) outputs 1600 lm with efficacy of 80 lm/W. It has a CRI of 80, color temperature of 2700K and is dimmable to 10%. The company said that based on the 25,000-hr rated life, the lamp would save consumers $220 over its life relative to an incandescent lamp.

The Sylvania design, like many other SSL retrofit lamps, uses a segmented architecture that mixes cooling channels and the optic globe. It is white in the off state and could probably pass for a legacy frosted light bulb.

You may note in the product name that the Sylvania lamp is in the A21 form factor as opposed to the A19 form factor that is most common in residential incandescent lamps. A21 lamps can have slightly longer necks than A19 lamps. The slight size difference matters little in many applications because they both use the same Edison socket base. But A21 lamps won’t fit in every application.

The Philips 100W-equivalent is also an A21 lamp. It delivers 1780 lm consuming 22W. Sylvania also wins the efficacy race by a nose.

GE Lighting, for its part in the race, said all along that it would be sometime in 2013 before it delivered the 1600-lm Energy Smart LED lamp (Fig. 6). But the company has steadfastly promised an A19 size. Ironically, the company will add components to the design to reach the smaller size.

The architecture comes at a price both in bill of materials and efficacy. GE hasn’t said what the lamp will cost, but the SynJet cooler will increase the components costs over passive heat sinks. Moreover, the 1600-lm design will use 27W because the SynJet does use a small amount of energy.

The startup dilemma

Returning to a theme we struck early on, new players in the retrofit lamp space face the challenge of trying to get to market quickly with an innovative design, and capturing share prior to saturation. No company is more instructive in the process than Switch Lighting.

We featured Switch Lighting on the cover of LEDs Magazine back in June of 2011 after their lamp design debuted in April of 2011. The design story was very compelling. The company would fill the globe of its lamp with liquid to draw heat away from the LEDs. At The LED Show last summer, CEO Tracy Bilbrough revealed the liquid to be silicone based (Fig. 7).

The reason for the delays in shipping are basically unknown to anyone outside the company. Surely the design is complex, and the pricing supports that fact. Seeing sample lamps over the course of 20 months, it’s apparent that the design went through a number of changes. The LEDs that are mounted facing outward around the center of the globe were once installed on aluminum fingers. Some type of printed-circuit board has replaced those fingers.

Fortunately for Switch, the company had an early start in the retrofit lamp race. They still have an opportunity to make money assuming the lamps deliver on the promised specs. A startup entering the market today facing a two year development cycle would have a tough time recouping the R&D expense with socket saturation looming.