This article was published in the February 2013 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete February 2013 issue, or view the E-zine version in your browser.

+++++

While several IC suppliers today offer dedicated switching ICs designed specifically for LED applications, the majority of these devices do not support DC-bus output voltage levels greater than 45V, with a few devices using advanced process technology that support up to 60V. The output-voltage limits the number of LEDs that can be driven in a series configuration where current is shared equally among each LED in the string. The limit to LEDs in a string can both limit the total lumen output of a solid-state lighting (SSL) design or the ability to implement a color mixing scheme – especially given that white LEDs have larger forward voltage (Vf) values than red LEDs. Driver developers, however, can use fixed-frequency and quasi-resonant (QR) flyback controllers to implement the DC-DC conversion stage and support higher DC voltages and more LEDs.

Let’s examine power-stage designs that can accommodate comparatively high DC bus voltage values. We will discuss a QR controller with minimal turn on losses and subsequent low electromagnetic interference (EMI). And we will discuss both fixed-frequency and QR controller designs with an added transistor to support dimming. SPICE (Simulated Program with Integrated Circuit Emphasis) simulation results will demonstrate each concept and extract the basic features of the QR controller, including valley switching and current limit, to prove the concept.

Typical applications for flyback controllers are in transformer-isolated AC-DC applications. These devices also possess features that allow them to be utilized effectively in DC-DC buck, or step-down, applications where supply voltages for accommodating larger strings of LED’s (50V and higher) are necessary. Additionally these controllers can be configured to support other useful features including dimming and programmable current capability.

Fixed-frequency and QR controllers

Both the fixed frequency and QR controllers (Figs. 1 and 2) contain an embedded power cell or start-up cell capable of working with high input-voltage values. Before the AC line voltage is fully applied and has stabilized, these internal cells provide a stable supply voltage to the IC so it can perform the necessary regulation. This is achieved by an internal switch that charges up the capacitor on the VCC terminals before the stabilization of the line voltage.

Once the line voltage stabilizes, the start-up cell becomes inactive unless power is interrupted. Under normal AC line conditions the IC derives its VCC power from a rectified AC source voltage. For either controller, voltages in excess of 270V can be supported at the IC input. This supported input voltage value is far greater than that supported by the typical DC-DC, fixed-frequency switching regulators that exist today for LEDs. As previously noted, most are only capable of handling maximum supply voltages of 60V (and more typically 45V).

Using the fixed frequency device is a quick and easy way to implement the DC-DC buck converter concept. Its drawback is that as a fixed switching frequency device it exhibits greater EMI than other available alternatives. Moreover the maximum supported duty cycle for these controller devices is between 80-85%. This means that the output voltage for the LED supply can only be 80-85% of the input voltage. As an example a 60V DC input bus would be limited to supporting a 48V DC output and 12-15 LED’s.

Quasi resonant advantages

For designs having stricter EMI standards and needing tighter differentials between the input and output voltage bus values, a QR device should be employed. The example in Fig. 2 uses Infineon’s ICE2QS03, which contains an integrated start up cell along with a digital frequency-reduction feature. QR operation minimizes EMI by turning on the field-effect transistor (FET) at the output during the zero crossing phase – a technique commonly known as valley switching. Another effect of turning on the FET at the zero crossing phase is reduced turn on losses, making this a very efficient switching solution for a DC-DC buck converter application. We shall see in a subsequent example how this solution also accommodates dimming applications.

Zero-voltage-switching operation occurs when there is a resonant condition resulting from inductor L1 and the FET output capacitance in the fully off state. Under this condition, capacitor voltage eventually begins to fall and the inductor current goes to zero.

We simulated this circuit concept using National Instruments Multisim SPICE software package. The inductor current and FET drain waveforms are shown in Fig 3. In this example the input voltage is 100V. The output voltage and Inductor L1 control the rise and fall time of the current. The turn on of the FET is initiated at the valley point once the FET drain to source voltage has been detected to reach its maximum value (100V). During this condition the FET is deemed off and is subsequently switched on by the QR controller. During this phase the inductor current rises and once the peak is reached the FET is fully on. At this point the FET is turned off and the inductor current discharges. The FET is fully off once the inductor current reaches zero and the drain to source reaches 100V.

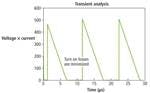

Fig. 4 illustrates the total average power (voltage×current) across the switching cycle and demonstrates how the QR controller concept minimizes losses during turn on. We performed average power simulations on this circuit design to determine the efficiency characteristics of this QR concept.

While simulation represents only a theoretical result of what is to be expected it nonetheless provides a good starting point for evaluating this concept. The analysis was conducted assuming ideal components (capacitors and inductors), so the designer can view the losses that are strictly attributed to the application of the QR topology.

Key figures from the analysis include an average output power of (96.4579+96.4551)/2= 96.45W and an average input power of (99.5510+97.3866)/2= 98.46. If you divide the output by the input we calculate converter efficiency of approximately 98%. As noted, this figure does not take into account the effect from non-ideal components and or imperfections in the circuit-board layout.

Dimming and current programming

In our circuit design, dimming can be implemented by applying a pulse-width modulation (PWM) input to the feedback (FB) pin and replacing the FB resistor with a photo bipolar junction transistor (BJT) placed in parallel with a current mirror transistor such as the BC846. When the paralleled configuration of the transistors is turned on, the FB pin is grounded and there is zero current.

Turning the transistors off sets the maximum current condition for the LED string. Thus by applying a PWM input, the resistance seen by the FB pin can be changed, which adjusts the current flow and establishes the dimming properties.

As previously mentioned, the ICE2QS03 QR controller has a digital-frequency-reduction property. Once lighter load conditions exist, such as during the dimming of the LED light engine, the controller subsequently reduces its switching frequency in accordance with the load. This positively impacts – reduces – the switching losses that are associated with the FET and the inductor under light load. Thus the controller operates at optimal efficiency for any load condition.

Added safety features

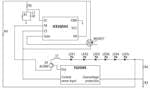

A further modification to the QR design introduces detection and protection circuitry, so that a break in the LED string does not create an overvoltage condition. This is illustrated in the block diagram in Fig. 5.

This design adds the TLE4305, which is a combination voltage and current regulator for switch-mode power supplies. This device is used in conjunction with the QR controller to provide the internal reference voltage needed for the current sense. It is an extremely low internal reference voltage (200 mV) thereby facilitating the use of smaller current sense resistors in the application.

The QR controller has a zero-crossing-detection (ZC) pin which performs multiple-functions. First in addition to performing the switch on of the MOSFET, once a valley condition has been detected, it also serves as the output overvoltage detector. In this case, when the output voltage exceeds a specified limit due to a broken LED string the QR controller will undergo a shutdown for protection purposes. The condition is triggered by the TLE4305 which detects the overvoltage condition via sense resistors and an internal reference voltage.

Flyback controller suits LEDs

We’ve seen that a flyback controller can serve efficiently in DC-DC applications where LED lighting is involved. Controllers that contain a high-voltage start-up cell can handle larger DC input voltages than switching ICs specifically designed for LED applications. This allows the designer to accommodate more LEDs in a series configuration, ensuring that current is shared equally by all LEDs in a string.

Likewise the driver designer has the option to program the desired current based on the use of PWM to define an operating point that establishes the desired LED current. The designer should also bear in mind that a QR controller enables full use of the available bus voltage because it is not bound to duty-cycle limitations typical in fixed frequency devices.

A significant feature of the QR controller scheme described here is that it also affords the designer optimal efficiency under dimming conditions compared to that offered by a fixed-frequency controller approach. Under light load conditions, the reduction of the QR controller’s switching frequency minimizes associated losses in the FET and inductor.

Sidebar: QR switching in the ICE2QS03

A review of the functions performed by the ICE2QS03 and each of the IC pins help illustrate the overall operational concepts discussed in the main article.

The zero current (ZC) pin takes in the voltage resulting from the oscillation dictated by the inductor and FET parasitic capacitance. Internally, this pin is connected to the zero-crossing detector for to determine the switch-on time of the FET for resonant operation.

The current sense (CS) pin is connected to the shunt resistor for primary current sensing externally, and to the PWM signal generator to in part determine the switch-off time for the FET. The controller ultimately uses the CS function and the voltage present at the feedback (FB) pin to determine when to switch the FET off.

The circuit operates by looking at the sensed voltage across the shunt resistor (CS) and the voltage is applied to an internal current measurement unit integrated inside the IC. The output voltage from the CS pin is compared with the regulation voltage that is represented by the FB input. Once this current sense voltage exceeds the FB voltage, the output flip-flop inside the IC is reset. As a result, the FET is switched off.