This article was published in the February 2012 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete February 2012 issue.

+++++

There is an enormous potential market for LED-based retrofit alternatives for legacy MR16 bulbs. But the varied electronic and magnetic transformers used to drive the halogen incandescent filaments in the legacy lamps aren’t a good match for LEDs. For lamp makers to deliver drop-in, solid-state lighting (SSL) replacement lamps and the energy savings and long life afforded by LEDs, the lamp designers will have to develop a universal driver circuit. An inverting buck-boost topology appears capable of the low-voltage MR16 challenge.

We will focus here on retrofits for low-voltage lamps as such products have offered numerous advantages leading to broad usage. For example, operating from a low-voltage AC source has allowed the use of thick filaments that do not snap as easily from mechanical shock or burn out as quickly as their AC-mains-connected cousins.

Designing a low-voltage retrofit is complicated by the fact that a transformer is part of the picture. Indeed millions, perhaps billions, of low-voltage transformers are installed inside lamp housings, behind walls and in ceilings. Building owners and consumers have no desire to remove the transformers and install a brand-new system designed specifically for LEDs. A true drop-in LED retrofit would be far less costly and still offer energy savings and long life.

The transformer challenge

There are two basic types of transformers used to step the mains AC voltage (120 VACRMS in North America or 230 VACRMS in the rest of the world) down to 12V. The older technology is a magnetic transformer, consisting of a ferromagnetic core and primary and secondary windings on the core. The second, newer technology, is the electronic low-voltage transformer (ELVT). The ELVT is really not a transformer but a switching-converter circuit that presents a much bigger challenge to designing an LED retrofit lamp. A drop-in replacement lamp must work with both types of transformers and there are many different design schemes used in ELVTs that further complicate the situation.

An electrical engineer who takes a first glance at low-voltage AC lighting is likely to assume that the task is simple, especially compared to bulbs with mains AC inputs. ICs such as DC-DC converters with constant-current outputs for LEDs are plentiful in the range of working voltages up to 30 VDC. Since 12VACRMS is about 18V peak, a simple diode bridge and a holdup capacitor are all that are needed to provide a fairly stable DC input voltage. The DC-DC converter can then be called upon to reject any ripple and deliver constant current to a varying number of LEDs.

The amount of capacitance needed for the classic diode-bridge and capacitor circuit can dictate a capacitor that is too large to fit into the shell of an MR16 bulb. Moreover, aluminum electrolytic capacitors are the only types that deliver the multiple hundreds of microfarads needed at the working input voltage of 18V, and those components are both bulky and prone to short lifetime when exposed to the unavoidable heat of the LEDs and power electronics.

Many existing LED MR16 lamps use the simple diode-bridge approach despite the liability of the capacitor. And in many cases this basic, low-cost design will work with magnetic transformers. Magnetic transformers are still often used in wet locations such as in outdoor garden-path lighting. Still the solution is less than ideal even in the case of a magnetic transformer because current spikes can damage or degrade both the LED driver electronics and the transformer, and can reduce the lifetime of the lamp.

Electronic low-voltage transformers

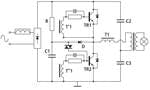

The ELVT presents a more difficult problem. Moreover, many makers of MR16 lighting systems have transitioned to ELVTs as a lower-cost, smaller, lighter, and generally more-power-efficient alternative to magnetic transformers. An ELVT switching converter operates over a range from 30 kHz to over 100 kHz. A small magnetic transformer forms part of the circuit to provide galvanic isolation. There are ELVT controller ICs available, but the cost constraints that accompany high-volume products such as MR16 lighting systems mean that most ELVTs used in lighting applications don’t have an IC or, for that matter, a control loop with a feedback circuit like the ones found in DC-DC or AC-DC power supplies. Instead, most ELVTs are self oscillating, using the half-bridge topology shown in Fig. 2.

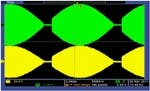

The plots reveal a key problem with ELVTs and LEDs. A typical low-voltage, halogen MR16 lamp draws anywhere from 25W to 50W. From an electrical standpoint the lamp load appears somewhat inductive, but mostly resistive. The ELVT is designed for that load.

In the region of each zero crossing in the signal envelope, even the relatively heavy load of a series of 50W halogen bulbs is not enough to get the converter started until a minimum voltage is reached. You see this in the dead zone following the end of each AC half-cycle in the plot. The ELVT doesn’t operate for some amount of time at the start of the subsequent half cycle.

A typical SSL MR16 uses three 1W LEDs and has an average-quality DC-DC converter LED driver circuit with a power efficiency of 80%. The input power is only 3.75W. To make matters worse, the impedance of a closed-loop DC-DC converter that might be used in the LED lamp is negative. The negative impedance is due to the fact that a closed-loop, switching converter draws less current as the input voltage increases and vice-versa, the opposite of how a resistor, or a halogen lamp, behaves.

A self-oscillating ELVT that was designed for a heavy resistive load, but is instead presented with a light load with negative impedance, can result in flickering light, audible buzzing, or a complete failure to start up. Our experiments show that a typical ELVT failed even when loaded with three 4W LED lamps. With a fourth 4W lamp added, the tested ELVT operated as intended.

Zero crossing problems

The zero crossings of an ELVT output can also prove problematic to the DC-DC converter in an LED MR16 lamp. Below some minimum voltage amplitude, the switching-control circuit in the converter will fail to operate. The result can be a DC-DC converter that is inactive for a significant portion of each half cycle.

A boost converter is also ineffectual because such a design can only step-up the output voltage. Temporary high-voltage peaks could create instances of uncontrolled current to the LEDs. To get the longest operation of the LED driver during each AC half-cycle and maintain control over LED current, a topology capable of stepping the output voltage both up and down is needed.

Inverting buck-boost regulator

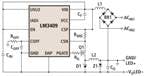

One approach to the problem is an inverting buck-boost regulator. Fig. 4 shows the complete circuit schematic of a buck-boost, LED-driver circuit used to solve the input-voltage, zero-crossing problem. Each LM3409 circuit draws an average input power of 4.9W while driving three white LEDs in series. The LM3409 is normally used to control a buck-regulator-based, constant-current LED driver, however by connecting the main inductor as shown in the schematic, a negative output voltage is developed with respect to the input voltage. More importantly, the absolute value of the output voltage can be greater than or less than the input voltage.

In buck regulators the average output current is equal to the average inductor current, hence LED current is kept constant. When the LM3409 is used as a buck-boost, however, two important characteristics change. First, in the buck-boost converter, average output current is no longer equal to average inductor current. Instead, the two quantities are related by a relatively simple equation that in fact makes output current directly proportional to input voltage.

Controlling the output current in proportion to the input voltage forces input current to be inversely proportional, which helps get ELVTs started by drawing a heavier load at the beginning of the AC half cycle where voltage is at or near zero. It also helps keep enough current flowing to keep ELVTs operating at the end of the AC half cycle, thereby delivering current to the LEDs over as much of that half cycle as possible.

An example driver circuit board (Fig. 5) demonstrates the applicability of the proposed topology to the MR16 applications. The outlined area in the photo is 20 mm long and the shape is conducive to MR16 usage.

EMC, inrush current and reliability

The proposed driver is able to operate with many ELVTs, even if only one bulb is connected, and provides additional benefits. The minimum of input capacitance and the use of input inductor L1 help to minimize the inrush-current spikes seen mostly at the beginning, but also at the end of each AC half cycle. Needing only a few microfarads of capacitance at both input and output means that no aluminium electrolytic capacitors are needed.

Low-voltage MR16 LED lamp design remains a challenge. Every ELVT is different. In the experience of the author, the price paid for a particular ELVT does not always correspond to the quality of the performance with light loads such as LED MR16 lamps. The investigation for this article was performed with four different ELVTs, all purchased on the open market, each of which was rated for an output power ranging from 10-20W on the low side to 60-70W on the high side. A single LM3409 buck-boost circuit operated properly with all four units. However, an additional ELVT rated for a minimum of 50W refused to start up at all. Therefore, a general guideline when selecting an ELVT for use with LED MR16 lamps is to buy one with the lowest minimum power rating available.