This article was published in the September 2013 issue of LEDs Magazine.

Visit the Table of Contents and view the E-zine version in your browser. You can download a PDF of the magazine from within the browser E-zine.

+++++

There is an old philosophical saying that you know quality when you see it, but at times it can be hard to describe. When it comes to describing the performance of a solid-state lighting (SSL) product, the design elements that impact quality are generally invisible. The LEDs that generate light are a small part of the overall system and only partially responsible for the quality of the system. It takes a systematic approach to a complete evaluation of an SSL product that will accurately project how a product might perform in the field at installation, and equally important over the product lifetime. Let's consider some examples of problematic design elements to set SSL developers on a course for success.

LED technology is rapidly evolving and many LED luminaire manufacturers in the marketplace make unsubstantiated claims regarding the color quality, lumens, efficacy, durability, and general quality of their SSL products. Poor quality SSL with inadequate thermal designs or poor circuit designs can create electrical over-stress conditions. These conditions, along with a chemical compatibility issue in the manufacturing process, can all result in LED quality degradation or even complete luminaire failure. Fig. 1 shows a collection of SSL design or process issues resulting in degradation or failure to the luminaire's LEDs.

Systematic evaluation

To ensure the quality of an SSL product, it is critical to perform a broad spectrum of tests on the luminaire system to accurately determine design margins and predict long-term reliability for the SSL product. It is not the LED alone but the total SSL system that has to be of quality. Cree has implemented a systematic testing process of a luminaire's Thermal, Electrical, Mechanical, Photometric, and Optical (TEMPO) parameters to assess the quality of an SSL product. The focus for TEMPO, under the Cree Services program, is to help remove technical barriers faced by LED customers. The program can help product developers rapidly overcome system design challenges, save on development costs, and improve time to market for new SSL products.

The proper procedure for system evaluation of a lighting product is a thorough multi-point testing and analysis process. Engineering personnel must perform a battery of thermal, electrical, mechanical, optical, and photometric tests and provide a comprehensive report that includes all relevant data necessary to confirm the performance of the LED lighting product. The list in the sidebar at the end of the article details the tests applied in the TEMPO program. In addition, the measured results from this testing are applied to the IES (Illuminating Engineering Society) approved TM-21 standard to project LED lifetime.

Measuring and evaluating an LED luminaire is challenging, particularly to lighting manufacturers that are new to designing with LEDs. A solid-state luminaire comprises many different subassemblies including the LEDs, circuit board, optics, diffuser, current driver, power supply, heat sink, and mechanical enclosure. Any of these components can affect the performance, quality, or lifetime of the SSL product.

The luminaire's system performance needs evaluation including mechanical construction and long-term reliability. Additionally, reports of measured results on the LED luminaires need to be based on the LM-79-08 standard. The evaluation should also offer a comparison of measured results to regulatory or safety requirements such as Energy Star, DesignLights Consortium (DLC), and UL criteria.

Thermal and mechanical testing

The majority of LED failures are temperature related; an LED's performance and projected lifetime correlate tightly to thermal management and the resulting junction temperature of the LED semiconductor chip. Elevated junction temperatures cause a reduction in light output and accelerated LED lifetime degradation. Proper thermal management of an LED luminaire and mechanical construction are vital for performance. To assess the mechanical construction, an evaluation should include techniques such as x-ray photographs of LED soldering. Measuring actual thermal performance to validate thermal design assumptions is necessary to ensure quality and reliability of SSL products.

However, thermal measurements of SSL can be challenging. Positioning the thermal couple at the wrong point or having large amounts of photonic energy illuminate the thermal couple will result in an incorrect temperature measurement. Such errors could result in design issues that may compromise LED lifetime for the finished product.

Proper testing should accurately measure the LEDs' solder-point temperatures validating the junction temperature of the LEDs in an SSL fixture. TEMPO testing, for example, provides a measured solder point temperature and an infrared thermal image of the luminaire at steady state, as well as a calculation of the junction temperature from these measurements. Temperature measurement tests and gradient infrared images, as shown in Fig. 2, help to measure and illustrate the thermal performance of LED-based luminaires.

Notice the difference in the thermal performance of the two identical printed circuit boards (PCBs) in the infrared photograph at the right of Fig. 2. The PCB on the left is cooler in temperature, shown as a yellow color, while the PCB on the right is bright red and the LEDs are white hot, indicating a thermal interface issue with the PCB mounted on the right.

The quality of the mechanical interface between the LEDs and the PCB, which is a major influence on the SSL system thermal performance, is evaluated using x-ray photography. The x-ray analysis of a PCB is useful to verify the quality of the soldering process and can determine whether there is voiding or excessive solder present. For the x-ray images, the camera head positioned above the LED dome with the focal plane at the solder pad boundary provides a clear indication of a quality solder interface. A large amount of solder voiding and excessive solder particles between the pads of the PCB is one example of a poorly soldered LED.

Electrical testing

Important electrical parameters to consider when evaluating SSL design are efficiency, power factor, driver current transient analysis, dimmer compatibility, and the overall luminaire efficacy. Fig. 3 shows examples of some of this electrical testing.

Driver efficiency, calculated by dividing the electrical output power supplied to the LEDs by the measured input power to the fixture, is a good performance metric of just the current driver of the SSL system. In this test, the output power to the LEDs is the sum of the product of the forward voltage and current for each LED.

Luminaire efficacy, sometimes referred to as wall plug efficacy, is a metric of how well the total fixture converts electrical energy into photons. The efficacy at steady state is calculated by dividing the total luminous flux measured in lumens by the total input power (lm/W). Efficacy is a good figure of merit for system performance since it is influenced by electrical, photometric, optical, and thermal performance. You can have a great light engine that produces a high lm/W output, but the total system may have an overall low efficacy due to high optical loss of an external lens or poor power efficiency of the current driver circuit providing drive current to the LEDs.

Power factor is another electrical metric for LED driver performance and often a key parameter for streetlighting due to the large number of these luminaires connected to the power grid. Meeting DesignLights Consortium (DLC) requirements for streetlighting requires that luminaires have a power factor greater than a specified value, typically 0.9. In general, the closer the value is to one, the better the performance.

A power factor of one indicates performance in which the voltage sourced by the utilities is in exact phase with the current consumed. On wide input voltage systems (as an example, 120 to 277 VAC), the power factor should be measured at all the nominal voltages across the input range (in this example, 120, 220, and 277 VAC). The worst-case measured power factor, typically at the highest nominal voltage, would then be reported in a DLC submittal.

Dimmer compatibility

Compatibility with dimmers can also be a critical quality factor, and while LEDs are easily dimmed, the SSL system and driver aren't easily designed for use with legacy phase-controlled dimmers intended for incandescent loads. Dimmer compatibility testing often involves connecting the SSL product to a set of commonly used dimmers and observing qualitatively any of the following characteristics: visible flicker, smoothness, dead travel, pop-on, audible noise, and dropout.

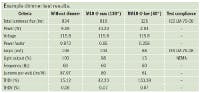

A recent standards publication from the National Electrical Manufacturers Association (NEMA) entitled "Phase cut dimming for solid state lighting: Basic compatibility" (SSL 7A-201X) defines dimmer circuits for maximum and minimum on-state conduction angle testing. The NEMA dimmer testing measurements include maximum light output (MLO) and reference minimum light output (RMLO) with a NEMA specified dimmer circuit. Examples of dimmer test results generated from using a NEMA specified dimmer circuit are summarized in the table.

Transient over-current events are also a significant degradation mechanism for LEDs. These transients are events that subject the LEDs to current that is higher than the maximum rated current on the LED data sheet. These transient over-current events, typically occurring for just fractions of a millisecond, result from hot plugging and turn on transient response from the current driver. These events are often a source of potential electrical overstress seen with LED drivers. High-speed, clamp-on current probes with digital storage oscilloscopes characterize and document the transient response. These electrical characteristics all need testing to help ensure the system quality of an SSL product.

Photometric and optical testing

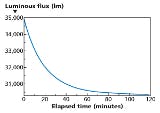

Photometric testing includes measurements of total radiant flux, luminous flux, chromaticity, correlated color temperature (CCT), and color rendering index (CRI). Radiant flux, expressed in watts, is a measurement of the total power of electromagnetic radiation (light) emitted from the luminaire or lamp. Luminous flux is a weighted measurement based on human visual perception. Mathematically, the measured radiant flux is convolved with the filter response of the human eye and is measured in units of lumens. Photometric measurements should be made at a recurring one-minute interval over a sufficient period to allow the fixture to reach thermal equilibrium.

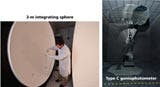

To conduct TEMPO photometric and optical tests, Cree utilizes a 2-m Labsphere integrating sphere, model CSLMS-7660, along with a Labsphere-Otsuka Electronics MC-9801 spectrometer. Photometric testing protocols should follow IES LM-79-081 and include procedures such as absorption correction using a NIST traceable lamp and ensuring the emission plane of the device under test is co-linear with the sphere's sensor baffle. In Cree's lab, power is applied to the unit being tested using a Chroma Model 61503 AC/DC power source, and a Xitron Model 2801 power analyzer is used to measure power.

Additionally, Cree employs a Type-C goniophotometer made by UL's Lighting Sciences business to measure the luminous intensity of a luminaire. These measurements are scans of the light beam of the luminaire under test at vertical angles through each of a series of lateral planes, i.e., a 3-dimensional beam pattern measured from various specific angles. Type C goniophotometers are required for IES LM-79-08 testing, since the LED luminaire under test is tested in the same manner as it would be operated in the field and without significant air movement to artificially cool the luminaire. Fig. 4 shows photographs of this photometric equipment.

As mentioned earlier, radiant flux is a measure of the total power of electromagnetic radiation emitted from the luminaire or lamp, while luminous flux is a measurement that is weighted based on human visual perception. For proper system characterization, luminous flux measurements should be recorded once per minute over a sufficient period of time to allow the test sample to reach stabilization per LM-79-08. In the case of the example test results shown in Fig. 5, this luminaire took approximately 1.6 hours to stabilize.

Materials and chemicals

The final steps of a systematic evaluation must focus on the materials and chemicals used in a product. Reactions over time and at elevated temperatures can compromise the LEDs and the SSL product performance.

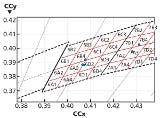

To ensure proper components are utilized and there is not any chemical degradation introduced by the manufacturing process, LEDs should be removed from a finished luminaire and fully characterized. Cree typically removes five LEDs from the luminaire under review and measures the photometric performance individually at the binning current of 700 mA. Fig. 6 depicts the results of a sample test plotted onto a binning chart. The LEDs are from the T3 flux bin (220 lm min. ±7%) and 6C1, 6D2, 7B4, and 7A3 chromaticity bins. That binning data can be compared to the LEDs specified for the SSL product to identify component degradation.

In summary, speed to market is critical in the SSL competitive landscape but so is a quality product. Cree is motivated to remove technical barriers and deliver the required measured system data quickly with its Thermal, Electrical, Mechanical, Photometric, and Optical (TEMPO) testing. This helps the SSL industry bring high-quality products to market in the shortest time possible. With proper system testing, report generation, and a consultation phone call to review the measured results the quality of a SSL product can be defined, helping ensure a higher-quality SSL product for the end consumer.

The Cree Durham Technology Center (NVLAP lab code 500070-0), located at Cree's headquarters in Durham, North Carolina, is accredited by The National Voluntary Laboratory Accreditation Program (NVLAP) to satisfy the requirements of ISO/IEC 17025:2005, IES LM-58-94, and IES LM-79-08 standards.

Summary of test measurements

Thermal:

- Solder point temperature measurement

- Thermal imaging with IR camera

Electrical:

- Driver efficiency

- Transient analysis

- Power analysis (PF, THD)

- Dimmer compatibility test

- Dielectric withstand (hi-pot)

- Vf/Current balancing (parallel arrays only)

Mechanical:

- Qualitative construction analysis

- Chemical compatibility analysis

- X-ray of printed circuit board

Photometric and optical:

- Luminous flux (lumens)

- Radiant flux (watts)

- Chromaticity (CRI, CCT, x-y, u-v, u'-v', duv)

- Spectral power distribution (visible range)

- Illuminance (ft-cd or lux)

- Luminous intensity (candela)

- Fixture efficacy (lm/W)

- Optical efficiency

- Component re-binning and color point evaluation

- Visual flicker

- TM-21 Lifetime estimate

- Review data against Energy Star and DLC criteria