This article was published in the March 2013 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete March 2013 issue, or view the E-zine version in your browser.

+++++

I think it was three years ago when I first heard Steve Paolini, founder of TeleLumen and CTO of Next Lighting, speak at Strategies in Light (SIL). He described the TeleLumen concept of light-scene playback in analogous terms to how we play MP3 tunes on our audio devices. I thought to myself, “Now here is a product that is really looking for those with a surplus of money.” Fast forward to SIL 2013 and Paolini’s vision is near mainstream reality, and the solid-state lighting (SSL) industry is calling for an even quicker pace of innovation with LED sources.I think SIL 2013 attendees likely came away understanding, and really believing, that light, especially LED light, is about far more than allowing us to read, chop onions safely, or get our work done. Indeed, LED-based products will clearly improve our performance or productivity through color tuning, and enable us to rest better in the future.

SIL, however, revealed far larger ramifications of what is quickly becoming our primary light source. In the article that I wrote on the conference (p. 26), I covered a presentation by Brad Koemer of Philips Lighting. He took the idea of integrated networks in lighting beyond controls to a vision of fundamental change in how buildings are designed and constructed.

In Koemer’s vision, we won’t ship 1000 troffer fixtures, 2000 downlights, 1000 spot lights, and 1000 wall sconces to a building construction site. Instead, we will ship 5000 standardized SSL modules to the site. Workers will install the building-block products into the ceilings and walls like any other building material, delivering what Koemer called mass customization of the lighting system. It’s a paradox in which mass-produced identical products enable far more customization implemented on the construction site.

The vision goes much further, because Koemer believes each module will carry intelligence about its own capabilities that are automatically transferred to the building system. Ultimately, commissioning becomes automatic and light sources are just one more element in a Building Information Management system. Combine color tuning with Koemer’s concept, and lighting can be adapted to boost productivity or even used to present digital animations.

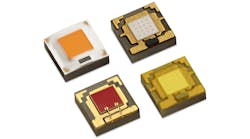

Back to color tuning, that technology is becoming mainstream. The use of white-LEDs mixed with red or amber LEDs to deliver efficient warm-white light has been available from companies like Cree and will be imminently available in LED or light-engine form for all lamp and luminaire manufacturers to leverage.

The future is even richer with more exact color mixes. Lumenetix demonstrated a product with a white LED channel combined with three color-LED channels, and soon we will see upwards of ten channels. LED component cost is headed down on a steep ramp (p.35). It will not be cost prohibitive for long to put extra LEDs in a product that never operates anywhere near its full flux-production capability.

And you can buy the color-tuning technology today in the form of the Philips Hue lamp that we have (covered previously). Just as we went to press I learned that Philips is about to make good on its promise to publish application programming interfaces (APIs) for Hue and sell a software development kit. These developments will allow third parties to develop software for Hue or hardware accessories. I don’t have full details, but I’m sure we will cover the news in our April issue.