This article was published in the November/December 2011 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete November/December 2011 issue.

+++++

Energy Star requirements for flat-panel televisions have become more stringent in recent years. If the Energy Star 6.0 proposal is accepted, it mandates that all TVs larger than 50 inches must consume no more than 85W of power by the fall of 2012. Two years ago, such TVs consumed close to 200W. These strict standards that attempt to curb power consumption worldwide have led to significant innovations in LCD TVs, especially in the backlight unit (BLU) which is a major source of power consumption. LED-based BLU can offer significant power reduction although the driver design must be optimized for the different direct- and edge-backlit schemes.

Display power refers to the power consumed by the LCD screen, BLU, and associated circuitry, and accounts for about two thirds of the total power consumed by a TV. Therefore, it would be logical for the industry to focus on reducing power consumption in this area.

Display power usage is high largely because the luminous efficiency of LCD TVs is very poor. An LCD panel has an extremely low transmittance level, in the 4-6% range, as the light travels from the BLU through the light guide, diffuser, optical film, and color filter. For example, if the BLU generates 8000-10000 cd/m² of luminance, then the final, visible-to-the-eye output might typically be between 380-450 cd/m2.

The BLU must therefore generate considerable light and consumes the largest amount of power inside an LCD TV. Any improvement in BLU efficacy will lead to dramatic power savings for the TV.

Not too many years ago, cold cathode fluorescent light (CCFL)-backlit LCD displays were the biggest power guzzlers inside LCD TVs. Much of the power consumed in CCFL BLUs is wasted because it is difficult to dim CCFL bulbs appropriately when the picture itself is dark. As a result, LCD TVs are rapidly transitioning to LED BLUs. LEDs inherently consume less power and also have significantly faster switching speeds. These characteristics make LEDs an ideal replacement for CCFL, enabling dimming to both improve picture quality and save energy.

LED backlight configurations

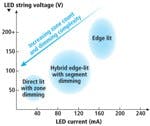

There are varying opinions about the best way to deploy LEDs for optimal cost, efficiency and picture quality. The various backlight configurations and their current and voltage requirements vary widely and result in different architectures and driver requirements. Fig. 1 shows the relative current and voltage characteristics of the three most common types of LED BLUs.

To improve picture quality and to benefit from the switching capability of the LEDs themselves, two other BLU schemes emerged with a heavy emphasis on dimming select portions of a screen. Direct-lit designs place LEDs directly behind the screen. Such designs can dim LEDs with fine granularity in small zones. Hybrid edge-lit designs place the LEDs on the side of the screen, but still support dimming of individual rectangular segments that extend horizontally across the screen. Both direct and hybrid schemes utilize dimming to significantly improve black levels, uniformity, and viewing angles, and reduce motion blur. Table 1 summarizes the BLU types and their characteristics.

Driving requirements and challenges

The different BLU schemes require significantly different driver architectures. Edge-type drivers typically require very high output voltages (a few hundred volts) that in most cases drive a single string of LEDs. Challenges related to driving multiple parallel strings such as matching current and forward voltages are a non-issue. However, this BLU style keeps all of the LEDs illuminated at all times, which wastes power. The only energy savings come from the baseline efficiency advantage of LEDs. The LEDs can be dimmed globally – the technique is sometimes called global dimming – but the dimming capability does not enhance the picture quality.

A driver for an edge-lit TV must utilize a high-voltage, boost topology. Typical voltage output from a TV power supply is 12-14V so this is used as an input supply to the driver circuit, which then boosts the voltage by a factor of 10-20 while still keeping the efficiency high.

The driver itself can be a discrete DC-to-DC design or, in certain instances, the main power supply can generate the high voltage directly from the AC input. Efficiency requirements for such drivers are between 90-95%. Typically over a hundred LEDs are strung together in series. Some designs do use multiple strings, typically 2-4, lowering the requisite string voltages.

The majority of LED-backlit TVs in the market today use the basic edge-lit design. The key challenge for edge-type drivers is to maintain high efficiency at the high voltage while keeping the overall component count low. Fig. 2 shows the typical driver architecture for edge-lit TVs.

Direct BLU driver issues

Fig. 3 shows the typical driver configuration for direct- and segment-edge-backlit TVs. The drive voltage is much lower than edge-lit designs, simplifying the issue of designing an efficient driver. A direct-backlit design would typically have a greater number of strings with fewer LEDs per string relative to a segment-edge design.

The main driver challenge in a direct-lit design is one of scale. Some such TVs have more than 100 strings or channels of LEDs. Typical drivers can handle 8-16 channels. So a TV can require many drivers.

In a typical direct-lit TV, LEDs chalk up about 40% of the total cost of the BLU bill of material, while the drivers make up another 20%. The cost of the LEDs, the power they consume, and the system complexity are all disadvantages.

Consider the issue of the varying forward voltages (Vf) of the LEDs. Even after sorting the LEDs, the varying forward voltages amongst the many strings causes a significant amount of power to be wasted inside the TV, producing heat and increasing the chance of thermal-stress-related LED failures.

Segment-edge drivers

The sheer number of LEDs and drivers required for direct BLUs, and the cost of those components, has been a key reason for the growing popularity of the segment-edge approach. Moreover picture quality is not the only purchase criteria consumers consider. In some cases thinner form factors are key selling points and the edge-segment scheme enables thinner TVs. More than 60 segment-edge-backlit TVs were announced in 2011 and this number is expected to grow rapidly in 2012.

Segment-edge dimmed TVs require anywhere from 12-48 channels of LEDs depending on the size of the TV and number of segments desired by the maker. Given the high channel counts, all of the challenges associated with drivers in direct-lit designs also apply here, albeit to a lesser degree. The aforementioned thermal problem persists and forces the TV maker to utilize several additional discrete components that add significant costs to the bottom line.

LED driver ICs have become a key disruptive technology that is enabling widespread adoption of LED-backlit TVs, especially considering their cost-savings potential. The types of drivers and the related BLU architectures will have to evolve with the innovations in LCD displays and TVs.

Segment-edge designs appear be the sweet spot of BLU architectures since they best satisfy the consumer’s dueling requirements for a quality picture and low cost. Still there may be increased demand for direct-backlit LCD TVs led by aggressive energy consumption mandates and demand for better video quality. New advancements in direct backlighting, such as multiple-zone sizes, fewer zones and super-selective current control will challenge traditional driver implementations to reduce costs even further.